News

13

June 2015

Hastelloy X Alloy- Complete Guide

Hastelloy Alloy X is an austenitic nickel based alloy comprising of 22% chromium for excellent resistance to oxidation at the elevated temperatures. It is designated as UNS N06002 or W. Nr – 2.4665, 2.4613 and enlisted in NACE MR – 01 – 75. Its forms are made in specifications – ASTM B435, AMS 5536, ISO 6208 and AECMA PrEn2185.

Hastelloy X alloy is solid solution strengthened, offering outstanding strength at high temperatures. It has great high temperature and stress rupture characteristics above 790oC or 1450oF. It is suitable for use in applications at temperature limits about 1200oC or 2200oF. Alloy X has high magnitudes of chromium, nickel and molybdenum that offer excellent corrosion resistance properties similar to high nickel alloys more commonly in corrosion applications.

Hastelloy X is basically known for providing high heat and oxidation resistance as well as excellent resistance to chloride stress corrosion cracking and outstanding resistance to reducing and carburizing conditions. It has been noticed to be extremely resistant to stress corrosion cracking in the petrochemical applications.

Alloy X has superior forming and welding properties. It is forgeable and because of its high ductility, it is easily cold worked. The work hardening rate of alloy is similar to the austenitic stainless steels. Good machining in the annealed form. It is weldable by fusion and resistance welding procedures. Hastelloy X is weldable through manual as well as automatic methods such as shielded metal arc welding, gas tungsten arc and gas metal arc welding processes.

Hastelloy X strips are generally offered in the solution heat processed conditions. While manufacturing, alloy X is solution heat processed at the elevated temperature above 1150oC and quickly quenched. If the heat processing and quenching are performed in the secured conditions, shining annealed products are offered.

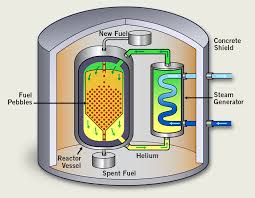

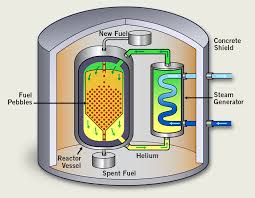

Use of Hastelloy X in gas cool reactor systems

Hastelloy X, a Nickel-Chromium- Iron-Molybdenum alloy is an essential structural alloy for components of gas cooled reactor equipments. It has been widely utilized for above two decades in the several high temperature applications that need high strength. It is basically a single phase alloy possessing face centered cubic structure and receives its strength basically by solid solution strengthening from the elements chromium, molybdenum and tungsten. The presence of large chromium concentration, it offers outstanding resistance to oxidation at temperatures above 982oC or 1800oF. Its most popular application is in gas turbine engines where it is utilized in the sheet forms.

Hastelloy X is made in specifications SB 35 section II and section VIII, in unfired pressure vessels. The latest design of steam cycle high temperature gas cooled reactor (HTGR), Hastelloy X is selected for the production of lower cross ducts that connect the exit of the reactor core to the steam generators. Similarly, the upper cross ducts that return the helium to the core are also produced of Hastelloy X. Several product forms such as plate, sheet, bar, forging and others are produced of this alloy.

The minor design temperature for the hot duct is 788oC or 1450oF with the probability of temperature level about 927oC or 1700 oF. The design service life is 280,000 hours in a condition of regularly recirculated and purified helium comprising of contaminated gases like water, carbon monoxide, methane and hydrogen. Hastelloy X is a chief alloy for materials of gas quenched reactor process heat units that are used for supplying heat for the coal conversion procedures such as hydrogasification, solution hydrocracking and steam gasification, steel production and others. Hastelloy X is used for ducting, tube or support plate materials of the moderate and process heat exchangers.

Alloy X shows a minimum in ductility by decreasing area over the temperature limit of 500 oC to 750oC. Such ductility minimum is standard in nickel base high temperature alloys. Tensile properties of Hastelloy X are as following:

Hastelloy X is made in specifications SB 35 section II and section VIII, in unfired pressure vessels. The latest design of steam cycle high temperature gas cooled reactor (HTGR), Hastelloy X is selected for the production of lower cross ducts that connect the exit of the reactor core to the steam generators. Similarly, the upper cross ducts that return the helium to the core are also produced of Hastelloy X. Several product forms such as plate, sheet, bar, forging and others are produced of this alloy.

The minor design temperature for the hot duct is 788oC or 1450oF with the probability of temperature level about 927oC or 1700 oF. The design service life is 280,000 hours in a condition of regularly recirculated and purified helium comprising of contaminated gases like water, carbon monoxide, methane and hydrogen. Hastelloy X is a chief alloy for materials of gas quenched reactor process heat units that are used for supplying heat for the coal conversion procedures such as hydrogasification, solution hydrocracking and steam gasification, steel production and others. Hastelloy X is used for ducting, tube or support plate materials of the moderate and process heat exchangers.

Alloy X shows a minimum in ductility by decreasing area over the temperature limit of 500 oC to 750oC. Such ductility minimum is standard in nickel base high temperature alloys. Tensile properties of Hastelloy X are as following:

It is well known that the fatigue and creep rupture properties of engineering alloys are affected by operation at high temperatures in the gaseous media. For engineering applications, the level of effect may be major or minor on the base of surface layer produced, the surface to volume ratio of the materials and kind of loading involved is static or dynamic. The level of reaction can be specifically described if the environment treats as a mass transfer source for oxidation, decarburization or carburization. These reactions can be specifically harmful if intergranular corrosion occurs, as grain boundaries weaken at the high temperatures. In air, the primary oxide to produce on Hastelloy X is a soft adherent layer of Cr2O3 that remains stable and secure as long as temperature reaches 982oC or exceeds. This security oxide layer makes Hastelloy X an outstanding material for high temperature applications in air. Exceeding 982oC or 1800oF, a volatile oxide layer CrO3 produces that is nonprotective.

The primary coolant of HTGR is helium and it comprises only small magnitudes of oxidizing layers. Therefore it is important to identify the nature of surface layers or corrosion products that may be created as a result of prolonged exposure such as about 28, 0000 hours to media. As latest ASME high temperature design allowable are based on mechanical characteristics like tensile, creep and fatigue that are produced in air, impact of HTGR prototypic conditions on the properties of alloys should be demonstrated for design.

Corrosion resistance

Hastelloy X offers outstanding oxidation resistance in air contributed by the exclusive oxidation resistant spinel that creates an external layer of duplex oxide. The prolong functionality of this material in non-oxidizing conditions, although where carburization may occur, needs to be determined. The oxidation level depends on the temperature as well as stress. The surface of the smaller stressed part of the alloy X component produces soft, green regular one micro-m thick oxide and without grain boundary corrosion. The surface layer is very thin at the stressed region of the sample about 20 to 30 micro-m deep penetrations. Unlikely, on the unstressed portion of the sample, an extremely thin oxide layer was produced without oxidation corrosion.

High temperature carburization rate of Hastelloy X in methane gas

Nickel based wrought alloy Hastelloy X tube is subjected to argon – methane at 800oC and 1000oC to evaluate the carburization mechanism of the alloy utilized for fuel injection nozzles of micro – gas turbine combustors.

Hastelloy X is commonly utilized as a high temperature alloy for gas turbine parts for example in combustors and fuel injection nozzles. It offers outstanding oxidation resistance in the elevated temperature oxidizing conditions by producing security chromium oxide layer. Although, it is widely subjected to low oxygen potential, high carbon containing conditions, specifically in the combustion media with methane and propane gases are commonly utilized. The chromium oxide security layer is considered unstable in these conditions may be unable to provide security. These carbonaceous gases cause carburization and in few cases, the metal dusting.

Carburization testing

The surface morphologies of the sample after carburization exposure (in argon or reacting gases) at 800oC to 1000oC for 1 to 100 hours are analyzed. The scratches from surface grinding can still be noticed after 25 hours of carburization at 800oC and the surface was shielded with a needle like reaction product after 100 hours. At temperature of 1000oC, the internal and outer surfaces of Hastelloy X tube were covered by a fine grained reaction product after 1 hour of carburization and fine grained product became coarser subsequent to prolong carburization. On the external surface, the coarse spherical shaped product was noticed after 25 hours of carburization and tended to develop more after 100 hours.

The cross- sections of the edges of sample tubes after carburization analysis at 800oC and 1000oC for different carburization periods are assessed. Internal carburization doesn’t occur at 800oC for minimum 25 hours of carburization; however it was noticed in some portions after 100 hours in the internal part of the tube. At 1000oC, the internally carburized layers were noticed to create after 1 hour and depth of every layer increased with the passage of time. The growth rate of internal and outer layers carburization sections was unlike in the smaller reaction periods. The depth of internal carburization region was larger than external region after 4 hours of corrosion however they became uniform after 9 hours.

While heating in running Argon, a thin chromium oxide scale may be produced on the Hastelloy X, due to contaminated oxygen in argon is still sufficient to produce chromium oxide (Cr2O3) layer. Its initially produced Cr2O3 layer may result in an incubation time before carburization and complete gas exchange in the reaction tube from argon to carburization argon – methane gas mixture requires some length of period around ten minutes. While the gas change, the internal part of the tube surface is subjected to Ar – CH4 before external region of the sample surface, causing in the smaller incubation period for the internal area of the tube surface.

Hot Working

Hastelloy high temperature alloys can be hot processed into several forms, although they can be more susceptible to the magnitude and rate of hot reduction than is for austenitic stainless steels. Besides, hot processing temperature limits for these alloys can be narrow. Specific care should be exercised while hot processing to attain the required outcomes. The features of solid solution strengthened high temperature alloys that are considered in following a specific hot working operation include – 1. Lower melting points 2. Large hot strength 3. Quick work hardening 4. Lower thermal conductivity. Additionally, the resistance to deformation in these alloys may increase quickly as the temperature reduces to the low end of the hot working limit. Following the hot working practices that include heavy initial and medium final reductions, combined with rapid reheating, usually offer the required outcomes. Moreover, the slow distortion rates reduce the adiabatic heating and applicable force necessities.

Forging

The following rules are generally followed in the forging of Hastelloy alloys-

Hastelloy X is made in specifications SB 35 section II and section VIII, in unfired pressure vessels. The latest design of steam cycle high temperature gas cooled reactor (HTGR), Hastelloy X is selected for the production of lower cross ducts that connect the exit of the reactor core to the steam generators. Similarly, the upper cross ducts that return the helium to the core are also produced of Hastelloy X. Several product forms such as plate, sheet, bar, forging and others are produced of this alloy.

The minor design temperature for the hot duct is 788oC or 1450oF with the probability of temperature level about 927oC or 1700 oF. The design service life is 280,000 hours in a condition of regularly recirculated and purified helium comprising of contaminated gases like water, carbon monoxide, methane and hydrogen. Hastelloy X is a chief alloy for materials of gas quenched reactor process heat units that are used for supplying heat for the coal conversion procedures such as hydrogasification, solution hydrocracking and steam gasification, steel production and others. Hastelloy X is used for ducting, tube or support plate materials of the moderate and process heat exchangers.

Alloy X shows a minimum in ductility by decreasing area over the temperature limit of 500 oC to 750oC. Such ductility minimum is standard in nickel base high temperature alloys. Tensile properties of Hastelloy X are as following:

Hastelloy X is made in specifications SB 35 section II and section VIII, in unfired pressure vessels. The latest design of steam cycle high temperature gas cooled reactor (HTGR), Hastelloy X is selected for the production of lower cross ducts that connect the exit of the reactor core to the steam generators. Similarly, the upper cross ducts that return the helium to the core are also produced of Hastelloy X. Several product forms such as plate, sheet, bar, forging and others are produced of this alloy.

The minor design temperature for the hot duct is 788oC or 1450oF with the probability of temperature level about 927oC or 1700 oF. The design service life is 280,000 hours in a condition of regularly recirculated and purified helium comprising of contaminated gases like water, carbon monoxide, methane and hydrogen. Hastelloy X is a chief alloy for materials of gas quenched reactor process heat units that are used for supplying heat for the coal conversion procedures such as hydrogasification, solution hydrocracking and steam gasification, steel production and others. Hastelloy X is used for ducting, tube or support plate materials of the moderate and process heat exchangers.

Alloy X shows a minimum in ductility by decreasing area over the temperature limit of 500 oC to 750oC. Such ductility minimum is standard in nickel base high temperature alloys. Tensile properties of Hastelloy X are as following:

| Temperature | Tensile strength | Elongation in 31.8 mm or 1.25 inch % | Reduction in area % | |||||

| oC | oF | 0.2 % yield | Ultimate | Complete | Uniform | |||

| 20 oC | 70 of | 359 Mpa | 52 ksi | 762 Mpa | 110.5 ksi | 50.5 % | 43.8 % | 59.8 % |

| 20 oC | 70 of | 349 Mpa | 50.6 ksi | 764 Mpa | 110.8 ksi | 51.5 % | 43.9 % | 59.2 % |

| 20 oC | 70 of | 350 Mpa | 50.8 ksi | 764 Mpa | 110.8 ksi | 51.9 % | 44.3 % | 61.4 % |

| 150 oC | 300 of | 290 Mpa | 42.1 ksi | 682 Mpa | 98.9 ksi | 51.1 % | 44.7 % | 60.6 % |

| 150 oC | 300 of | 288 Mpa | 41.8 ksi | 671 Mpa | 97.3 ksi | 51.5 % | 45.9 % | 59.8 % |

| 290 oC | 550 of | 248 Mpa | 36 ksi | 662 Mpa | 96 ksi | 52.8 % | 46.2 % | 57.9 % |

| 290 oC | 550 of | 244 Mpa | 35.4 ksi | 651 Mpa | 94.4 ksi | 53.7 % | 48.3 % | 55.9 % |

| 290 oC | 550 of | 245 Mpa | 35.5 ksi | 656 Mpa | 95.2 ksi | 54.4 % | 49.9 % | 55.4 % |

| 430 oC | 800 of | 223 Mpa | 32.4 ksi | 627 Mpa | 91 ksi | 56.5 % | 51.1 % | 56.9 % |

| 430 oC | 800 of | 234 Mpa | 34 ksi | 629 Mpa | 91.2 ksi | 49.8 % | 47.3 % | - |

| 480 oC | 900 of | 193 Mpa | 28 ksi | 623 Mpa | 90.4 ksi | 59 % | 53.6 % | 43.6 % |

| 480 oC | 900 of | 234 Mpa | 34 ksi | 622 Mpa | 90.2 ksi | 55.9 % | 53 % | 38.4 % |

| 480 oC | 900 of | 219 Mpa | 31.8 ksi | 621 Mpa | 90.1 ksi | 58.4 % | 53.6 % | 48.2 % |

| 540 oC | 1000 of | 239 Mpa | 34.6 ksi | 592 Mpa | 85.8 ksi | 49.9 % | 46.5 % | 40.9 % |

| 540 oC | 1000 of | 221 Mpa | 32.1 ksi | 596 Mpa | 86.5 ksi | 48.8 % | 43.9 % | 31.4 % |

| 595 oC | 1100 of | 220 Mpa | 31.9 ksi | 585 Mpa | 84.9 ksi | 53.3 % | 47.9 % | 40.9 % |

| 595 oC | 1100 of | 223 Mpa | 32.4 ksi | 587 Mpa | 85.1 ksi | 53.1 % | 47.7 % | 41.9 % |

| 595 oC | 1100 of | 232 Mpa | 33.7 ksi | 581 Mpa | 843 ksi | 51.5 % | 47 % | 43 % |

| 650 oC | 1200 of | 214 Mpa | 31.1 ksi | 507 Mpa | 73.6 ksi | 39.7 % | 39.4 % | 35.9 % |

| 650 oC | 1200 of | 213 Mpa | 30.9 ksi | 507 Mpa | 73.6 ksi | 39.7 % | 37.9 % | 39.4 % |

| 705 oC | 1300 of | 223 Mpa | 32.4 ksi | 425 Mpa | 61.6 ksi | 48.5 % | 23 % | 41.7 % |

| 705 oC | 1300 of | 215 Mpa | 31.2 ksi | 452 Mpa | 65.5 ksi | 37.3 % | 29.9 % | 33.6 % |

| 705 oC | 1400 of | 212 Mpa | 30.8 ksi | 460 Mpa | 66.7 ksi | 37.6 % | 30.8 % | 35.9 % |

| 760 oC | 1400 of | 215 Mpa | 31.2 ksi | 320 Mpa | 46.4 ksi | 73.3 % | 6.4 % | 66.1 % |

| 760 oC | 1400 of | 217 Mpa | 31.5 ksi | 323 Mpa | 46.9 ksi | 75.6 % | 7.8 % | 68.8 % |

| 760 oC | 1400 of | 217 Mpa | 31.5 ksi | 385 Mpa | 55.8 ksi | 66.6 % | 11.7 % | 55.8 % |

| 760 oC | 1400 of | 206 Mpa | 29.9 ksi | 381 Mpa | 55.2 ksi | 68.1 % | 12 % | 57 % |

| 815 oC | 1500 of | 221 Mpa | 32.1 ksi | 241 Mpa | 34.9 ksi | 87.2 % | 3 % | 78.9 % |

| 815 oC | 1500 of | 232 Mpa | 33.7 ksi | 240 Mpa | 34.8 ksi | 72.2 % | 3.4 % | 74.3 % |

| 815 oC | 1500 of | 231 Mpa | 33.5 ksi | 238 Mpa | 34.5 ksi | 74.6 % | 3.2 % | 77.1 % |

| 815 oC | 1500 of | 213 Mpa | 30.9 ksi | 241 Mpa | 34.9 ksi | 81.2 % | 3.2 % | 81.4 % |

| 815 oC | 1500 of | 225 Mpa | 32.7 ksi | 288 Mpa | 41.7 ksi | 86 % | 5.8 % | 69.6 % |

| 870 oC | 1600 of | 161 Mpa | 23.4 ksi | 165 Mpa | 24 ksi | 79.8 % | 2.1 % | 88.9 % |

| 870 oC | 1600 of | 163 Mpa | 23.6 ksi | 168 Mpa | 24.3 ksi | 84.4 % | 2.3 % | 88.2 % |

- Ingots minimum 30 minutes are kept at the forging temperature for complete thickness, calibrated optical pyrometer is necessarily used.

- The stock should be turned immediately to demonstrate the cooler side to the furnace condition. The direct flame impingement on the alloy should be prevented.

- Forging should start quickly subsequent to retrieving metal from the furnace. A small period lapse may permit the reduction in the surface temperature from 38oC to 93oC or 100 to 200oF. Do not increase the forging temperature to recompense the heat as it may result in the premature melting. Reasonably extreme reductions are advantageous to retain the internal heat as much as feasible, hence decreasing grain coarsening and count of reheating. Reductions above 40% in each session are unsuitable.

- Care should be taken to provide adequate hot work while forging to ensure that suitable structure and features are obtained in the eventual components. For components with large areas, it is recommended to include several forging upsets in the warm working period to permit for sufficient forging reductions.

- Light reduction finish sizing are not followed in the normal instances. However if needed that should be conducted at the minimum limit of the forging temperature.

- Radical changes are not made in the cross – section shape like moving from a square to circular, while initial forming levels. Rather move from square to circular cornered square to octagon to circular.

- Fix the fractures or wears if produced any while forging. Usually it is performed at the moderate levels in the forging sessions.