News

22

June 2020

Potential of nickel alloys for use in halide based industrial conditions

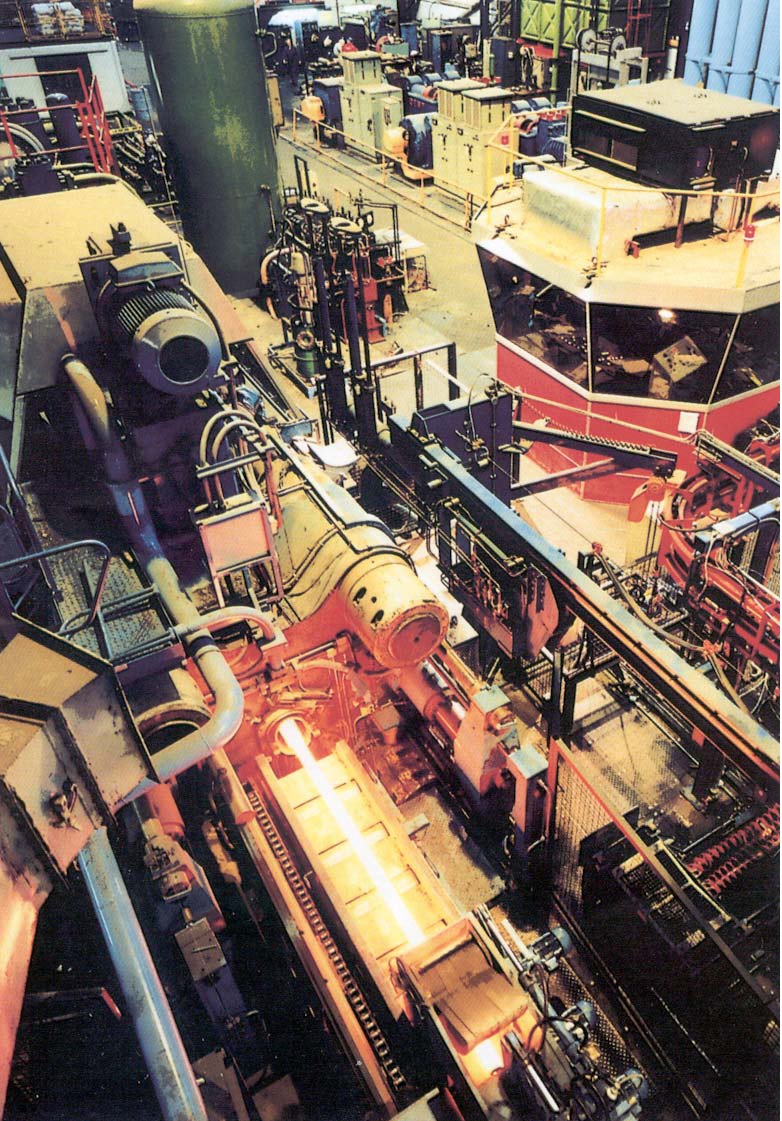

Nickel alloys and stainless steels are widely used in various industrial applications which demand heat and corrosion resistance or one of both. Nickel is one of the well know materials for offering resistance to diverse caustic solutions and molten caustic. Different nickel alloys are commonly used in sodium hydroxide production and in several other plants involving the use of caustic solutions.

The cyclic voltammetry method is required to determine the steps used in the overall reactions causing the development of different layers on the metallic materials. It is specifically useful for distinguishing the products developed by chemical or electrochemical reactions.

Pitting corrosion

Pitting corrosion of a specific metal or alloy occurs in a specific potential range in the passive zone. The development and progress of a specific type of corrosion on the metallic surface occurs in solutions comprising vigorous chloride, bromie and iodide ions. The critical potential at which pitting occurs and is based on various factors including the type and concentration of attacking anion, type of metal used and relative concentration of other anions.

The corrosion behavior of nickel, nickel alloys and stainless steel in different concentrations of nitric acid solutions by using the cyclic voltammetry method was evaluated. Also the pitting corrosion of these samples in chloride based solutions and its prevention by some inorganic compounds by using anodic polarization was also evaluated. The cyclic voltammetry of nickel, Inconel 600, Incoloy 800 and SS 316 electrodes were evaluated in NaOH solution as a function of NaOH concentration. The influence of chloride ion as a pitting corrosion agent on the voltammetry and potentiodynamic anodic polarization of nickel, Inconel 600, Incoloy 800 and SS316 electrodes in NaOH solution was further evaluated.

There is a sufficient proof related to the development of Ni(OH)2 in alkaline solutions in the potential range related to the anodic current of peak. From considering the charge magnitudes under peak, various studies show the development of a mono-layer of Ni(OH)2 on the electrode surface. It has been observed that Ni(OH)2 seems as hydrated species on the metal surface, once its solubility product is exceeded.

For Incoloy 800 which comprises nickel and iron, responds to the oxidation of nickel and iron to Ni hydroxide and iron hydroxide. When SS 316 is used, it may correspond to the development of Iron hydroxide. After peak, there is a passive region. The current passing along this region is referred as the corrosion current which is used to counteract the chemical dissolution of the passive layer. The alkali concentration has no considerable effect on the current flowing along the CV as for nickel.

Pitting corrosion of metallic materials occurs when the passivity breakdown of local points on the surface subjected to the corrosive condition, whilst the major part remains passive. Practically, the pitting may occur when the corrosive conditions comprise chloride or other vigorous halide ions. You should consult with material engineers to determine the suitability of Inconel bars in halide ions conditions and find out which alloy is better for use.

Nickel alloys and stainless steels are widely used in various industrial applications which demand heat and corrosion resistance or one of both. Nickel is one of the well know materials for offering resistance to diverse caustic solutions and molten caustic. Different nickel alloys are commonly used in sodium hydroxide production and in several other plants involving the use of caustic solutions.

The cyclic voltammetry method is required to determine the steps used in the overall reactions causing the development of different layers on the metallic materials. It is specifically useful for distinguishing the products developed by chemical or electrochemical reactions.

Pitting corrosion

Pitting corrosion of a specific metal or alloy occurs in a specific potential range in the passive zone. The development and progress of a specific type of corrosion on the metallic surface occurs in solutions comprising vigorous chloride, bromie and iodide ions. The critical potential at which pitting occurs and is based on various factors including the type and concentration of attacking anion, type of metal used and relative concentration of other anions.

The corrosion behavior of nickel, nickel alloys and stainless steel in different concentrations of nitric acid solutions by using the cyclic voltammetry method was evaluated. Also the pitting corrosion of these samples in chloride based solutions and its prevention by some inorganic compounds by using anodic polarization was also evaluated. The cyclic voltammetry of nickel, Inconel 600, Incoloy 800 and SS 316 electrodes were evaluated in NaOH solution as a function of NaOH concentration. The influence of chloride ion as a pitting corrosion agent on the voltammetry and potentiodynamic anodic polarization of nickel, Inconel 600, Incoloy 800 and SS316 electrodes in NaOH solution was further evaluated.

There is a sufficient proof related to the development of Ni(OH)2 in alkaline solutions in the potential range related to the anodic current of peak. From considering the charge magnitudes under peak, various studies show the development of a mono-layer of Ni(OH)2 on the electrode surface. It has been observed that Ni(OH)2 seems as hydrated species on the metal surface, once its solubility product is exceeded.

For Incoloy 800 which comprises nickel and iron, responds to the oxidation of nickel and iron to Ni hydroxide and iron hydroxide. When SS 316 is used, it may correspond to the development of Iron hydroxide. After peak, there is a passive region. The current passing along this region is referred as the corrosion current which is used to counteract the chemical dissolution of the passive layer. The alkali concentration has no considerable effect on the current flowing along the CV as for nickel.

Pitting corrosion of metallic materials occurs when the passivity breakdown of local points on the surface subjected to the corrosive condition, whilst the major part remains passive. Practically, the pitting may occur when the corrosive conditions comprise chloride or other vigorous halide ions. You should consult with material engineers to determine the suitability of Inconel bars in halide ions conditions and find out which alloy is better for use.